MOL PLUS to invest in EneCoat Technologies

MOL PLUS has announced its intent to invest in EneCoat Technologies, a spin-off company from Kyoto University that develops perovskite solar cells and related materials.

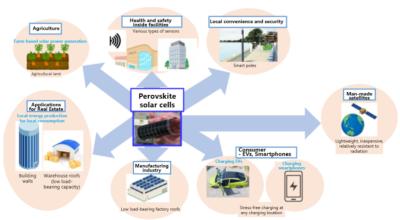

MOL PLUS stated it is "pleased to participate in this fundraising" and views the widespread use of perovskite solar cells as a revolutionary solution that will enable power generation anywhere, indoors or outdoors. Moving forward, the MOL Group plans to study a wide range of applications in the port, logistics, and real property fields, including installation on the decks of freighters and on the roofs and walls of port facilities such as warehouses and terminal cargo handling centers.