Current photovoltaic (PV) panels typically contain interconnected solar cells that are vacuum laminated with a polymer encapsulant between two pieces of glass or glass with a polymer backsheet. This packaging approach is common in conventional photovoltaic technologies such as silicon and thin-film solar modules, contributing to thermal management, mechanical reinforcement, and environmental protection to enable long lifetimes. Commercial vacuum lamination processes typically occur at 150 °C to ensure cross-linking and/or glass bonding of the encapsulant to the glass and PV cells. Perovskite solar cells (PSCs) are known to degrade under thermal stresses, especially at temperatures above 100 °C.

Researchers from NREL and The Dow Chemical Company have examined degradation modes during lamination and developed internal diffusion barriers within the PSC to withstand the harsh thermal conditions of vacuum lamination.

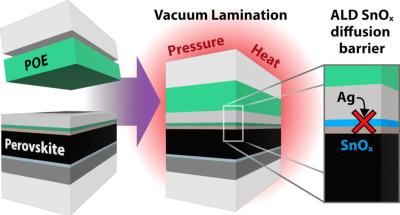

PSCs with self-assembled monolayers at the ITO interface and SnOX layers deposited by atomic layer deposition at the electron extraction side of the device endured vacuum lamination at conditions typical of commercial PV processes (150 °C) without degradation.

In this recent work, the team set out to bridge the gap between innovative perovskite technology and established PV fabrication processes, facilitating the integration of PSCs into existing manufacturing infrastructures. The research systematically explored the effects of varying lamination process parameters, specifically temperature and duration, as well as the selection of materials for both the PSCs and the polymeric encapsulants.

In the PSC, the team varied the hole transport layer (HTL) and the buffer layer (BL) for the electron transport layer (ETL) to explore the durability during vacuum lamination. they determined that self-assembled monolayer (SAM) HTL materials such as [2-(9H-carbazol-9-yl)ethyl]phosphonic acid (2PACz), and [2-(3,6-dimethoxy-9H-carbazol-9-yl)ethyl]phosphonic acid (MeO-PACz) are more durable to lamination than poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine (PTAA). Tin oxide (SnOX) grown by atomic layer deposition (ALD) is more robust to lamination than widely used bathocuproine (BCP) as the ETL buffer layer.

The scientists proposed silver (Ag) diffusion as the primary degradation mechanism during vacuum encapsulation by studying different permutations of PSC device materials and encapsulants and employing a variety of characterization techniques. They demonstrated that SAM HTLs coupled with a SnOX ETL buffer layer as an internal diffusion barrier mitigate silver diffusion to facilitate vacuum lamination of PSCs at 150 °C ─ standard practice for the PV industry.

This work demonstrates that perovskite PV can be integrated into the existing module lamination process, enabling future single- and multijunction modules utilizing perovskite absorbers.