NREL team builds comprehensive manufacturing cost model for perovskite/silicon tandem solar modules

Increasing module efficiency and expanding manufacturing capacity play complementary roles in reducing costs of metal halide perovskite/silicon tandem solar modules, according to researchers at the U.S. Department of Energy's National Renewable Energy Laboratory (NREL). Each cost lever can play a similar role depending on a manufacturer’s ability to scale up and improve module performance.

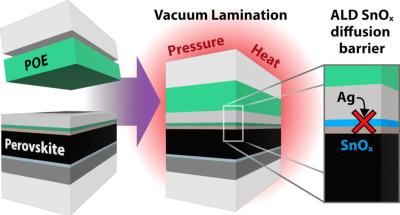

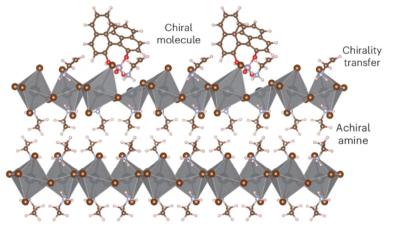

They explain that tandem PV technology, created by pairing silicon with metal halide perovskites (MHPs) for example, can help create a solar module that can convert more sunlight to electricity than using silicon alone. This tandem technology is still in the early stages, and there are multiple options being pursued to integrate MHPs and silicon, with a lot of unknowns in terms of cost and performance. To address this gap, the researchers built a manufacturing cost model that combines laboratory processes with existing equipment and supply chains to compare different possible approaches at scale.