Perovskite Quantum Dots (PQDs)

Perovskites are materials that share a crystal structure similar to the mineral called perovskite, which consists of calcium titanium oxide (CaTiO3).

Depending on which atoms/molecules are used in the structure, perovskites can possess an impressive array of interesting properties including superconductivity, ferroelectricity, charge ordering, spin dependent transport and much more. Perovskites therefore hold exciting opportunities for physicists, chemists and material scientists.

Quantum dots (QDs), sometimes referred to as semiconducting nanocrystals (NCs), are miniscule particles of a semiconducting material with diameters in the range of 2-10 nanometers (10-50 atoms). Quantum dots have properties labeled as intermediate between bulk semiconductors and discrete atoms or molecules. Their optoelectronic properties change as a function of both size and shape. QDs demonstrate optical and electronic properties different from those of larger particles. In fact, QDs tend to exhibit quantum size effects in their optical and electronic properties, like tunable and efficient photoluminescence (PL), with narrow emission and photochemical stability. This is why QDs have been incorporated as active elements in a wide variety of devices and applications, some of which are already commercially available, such as QD-based displays.

Perovskite quantum dots (PQDs) are a class of quantum dots based on perovskite materials. While these are relatively new, they have already been shown to have properties matching or surpassing those of the metal chalcogenide QDs: they are more tolerant to defects and have excellent photoluminescence quantum yields and high colour purity. Such attractive properties are extremely suited for electronic and optoelectronic applications and so perovskite quantum dots have significant potential for real world applications, some of which are already emerging, including LED displays and quantum dot solar cells.

Perovskite QDs could enable stable quantum emitters

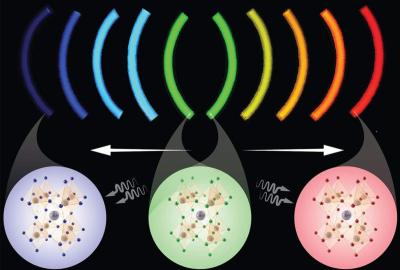

Researchers from the University of Oklahoma (OU) and Northwestern University recently addressed light emission problems prevalent in quantum applications. Quantum light sources can flicker like stars and fade out like, but the team's recent research proves that adding a covering to one of these light sources, called a colloidal quantum dot, can cause them to shine without faltering, opening the door to new, affordable quantum possibilities.

Sythensized QDs suspended in solvents under laser irradiation. Image credit: Eurekalert and Jonathan Kyncl

The study, led by OU Assistant Professor Yitong Dong, demonstrates that adding a crystalized molecular layer to QDs made of perovskite neutralizes surface defects and stabilizes the surface lattices. Doing so prevents them from darkening or blinking.

UbiQD acquires BlueDot Photonics

UbiQD, a developer and manufacturer of quantum dot technology, has acquired BlueDot Photonics. The deal includes perovskite-based quantum cutting technology and exclusive rights to BlueDot’s associated intellectual property, initially developed (and licensed from) the University of Washington.

Seattle-based BlueDot Photonics develops solutions to improve solar panel performance. BlueDot's doped perovskite materials convert high-energy photons into nearly twice as many lower-energy photons, according to the company, and the technology could increase silicon solar panel efficiency by up to 16%. The technology has the potential to reduce the cost of solar energy generation and push photovoltaic performance beyond the theoretical limits of traditional silicon-based cells.

New light-powered technique enables precision tuning of perovskite quantum dots

North Carolina State University researchers have demonstrated a new technique that uses light to tune the optical properties of quantum dots – making the process faster, more energy-efficient and environmentally sustainable – without compromising material quality.

“The discovery of quantum dots earned the Nobel Prize in chemistry in 2023 because they are used in so many applications,” says Milad Abolhasani, corresponding author of a paper on the work and ALCOA Professor of Chemical and Biomolecular Engineering at NC State. “We use them in LEDs, solar cells, displays, quantum technologies and so on. To tune their optical properties, you need to tune the bandgap of quantum dots – the minimum energy required to excite an electron from a bound state to a free-moving state – since this directly determines the color of light they emit. Existing methods for bandgap tuning of perovskite quantum dots rely on chemical modifications or high-temperature reactions, both of which are energy-intensive and can introduce inconsistencies in the final material properties. Our new approach uses light to drive the reaction, which requires less energy and allows us to be incredibly precise.”

Perovskite-Info launches a new edition of its Perovskite for Displays Market Report

Perovskite-Info is proud to announce an update to our Perovskite for the Display Industry Market Report. This market report, brought to you by the world's leading perovskite and OLED industry experts, is a comprehensive guide to next-generation perovskite-based solutions for the display industry that enable efficient, low cost and high-quality display devices. The report is now updated to February 2025, with all the latest commercial and research activities.

Reading this report, you'll learn all about:

- Perovskite materials and their properties

- Perovskite applications in the display industry

- Perovskite QDs for color conversion

- Prominent perovskite display related research activities

The report also provides a list of perovskite display companies, datasheets and brochures of pQD film solutions, an introduction to perovskite materials and processes, an introduction to emerging display technologies and more.

Researchers demonstrate spray-drying fabrication of perovskite quantum-dot-embedded polymer microspheres for display applications

Researchers from China's Beihang University, Beijing Institute of Technology, Chinese Academy of Sciences and Zhijing Nanotech (Beijing) have reported the spray-drying fabrication of perovskite quantum dot (PQD) microspheres from a precursor solution at a scale of 2000 kg∙a−1.

The obtained PQDs were embedded in polymer microspheres, resulting in a high photoluminescence quantum yield and enhanced stability. By controlling the precursor concentration, the average size of the polymer microspheres can be tuned from 41 to 0.44 μm. The as-prepared PQD-embedded polymer microspheres were mixed with ultraviolet adhesive to fabricate PQD-enhanced optical films for liquid crystal display (LCD) backlights.

Powering Tomorrow: Solaveni's CEO Discusses Breakthroughs in Green Perovskite Materials

When it comes to innovation in advanced materials, Solaveni GmbH stands out as a company with a bold mission. Founded in 2021 as a subsidiary of Saule Technologies, Solaveni was created with a vision to revolutionize the world of perovskite-based materials by focusing on sustainable chemistry and environmental responsibility. Today, the company is carving out a space in fields like printed electronics, energy harvesting, storage, and solid-state lighting, all while ensuring its processes remain green and future-ready.

At the heart of Solaveni’s journey is its CEO, Dr. Senol Öz, whose expertise and passion for perovskite technology have been key to the company’s progress. Senol’s career spans over a decade of research and hands-on experience in solution-processing and chemical engineering of perovskite solar cells. From his doctoral work in Germany, to his postdoctoral research in Japan, and eventually joining Saule Technologies, his path has been defined by a deep commitment to advancing perovskite materials.

We had the opportunity to sit down with Senol for an insightful Q&A, where he shared his thoughts on Solaveni’s vision, the challenges of perovskite technology, and the future of sustainable material production. Let’s dive into the conversation!

Solaveni was established in 2021 as a subsidiary of Saule Technologies, one of the pioneers in the perovskite solar industry. Why did Saule decide to establish a materials subsidiary?

Saule Technologies, a trailblazer in the perovskite solar industry, founded Solaveni in 2021 to address the burgeoning demand for high-quality, innovative materials critical to advancing solar technology. The establishment of Solaveni reflects Saule’s strategic vision to enhance and diversify its capabilities within the renewable energy sector. By creating a specialized subsidiary, Saule aims to streamline the development and production of materials relevant for the perovskite ecosystem, ensuring consistent quality and fostering innovation.

We interview Sofab Inks' CEO & COO, discussing the company's materials, business, and industry outlook

Sofab Inks develops and produces advanced materials for perovskite solar cells. The company's flagship product is a solvent-based tin oxide ETL that has already seen promising results in improving the performance and lifespan of perovskite solar cells. We interviewed the company's CEO Blake Martin and COO Jack Manzella, who help us understand the company's materials and business better. Click here to contact Sofab Inks to learn more or request a material sample.

Hello Blake and Jack. Earlier this year, Sofab Inks launched Tinfab, a high-performance and low-cost ETL material for perovskite solar cells. Can you detail the market reaction for your new material, and also the performance benefits that one can expect from this new ETL?

Since launching Tinfab, we’ve experienced significant interest across the industry, with approximately 40 companies and universities currently testing the material in perovskite solar cell applications. This strong engagement underscores the market's demand for innovative, scalable ETL solutions.

Tinfab is designed to fully replace C60/fullerenes in perovskite solar cells, addressing key limitations of C60, including lower stability, higher costs, and the complexity of vacuum deposition. Unlike C60, Tinfab can be solution-deposited in ambient environments, making it far more suitable for scalable manufacturing.

Avantama to sell its perovskie QD IP portfolio

Switzerland-based Avantama, a leader in high-tech materials for electronics, has brought its perovskite QD (pQD) technology to “market-ready” level. Avantama's CEO, Dr. Samuel Halim states that reliability (as QD film) was confirmed by leading display supply chain partners, the pQD production has been established in-house and the pQD film production has been established at a leading Asian film maker.

Now, as part of a move to bring Avantama’s pQD market-ready technology into the hands of a company with market and customer access, Ocean Tomo Transactions (a part of J.S. Held) will be representing Avantama in the sale of its pQD IP portfolio and related know-how and manufacturing assets.

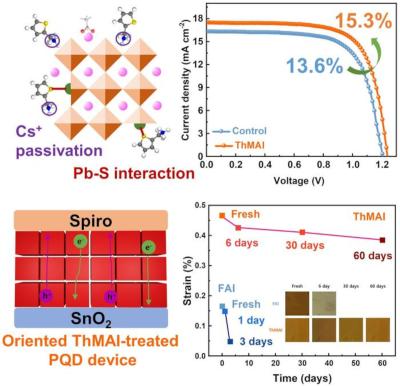

New ligand exchange process enables improved perovskite quantum dots for efficient and stable solar cells

Researchers from Korea's Daegu Gyeongbuk Institute of Science and Technology (DGIST), Gyeongsang National University (GNU) and Kookmin University have developed a method to improve both the performance and the stability of solar cells using perovskite quantum dots. They developed longer-lasting solar cells by addressing the issue of distortions on the surface of quantum dots, which deteriorate the performance of solar cells.

A schematic diagram of bilateral ligand bonding on the surface of perovskite quantum dots. Image credit: Chemical Engineering Journal

Perovskite quantum dots can have excellent light-to-electricity conversion capabilities and are easy to mass-produce. However, according to the research team, in order to utilize them in solar cells, the ligands attached to the quantum dot surface must be replaced. This process often leads to distortions of the quantum dot surface, resembling crumpled paper, which results in decreased performance and shorter lifespans for the solar cells. To address this issue, the team adopted short ligands that securely hold the quantum dots from both sides, effectively uncrumpling the distorted surface. The ligands help restore the distorted lattice structure, smoothing the crumpled surface of the quantum dots. This significantly reduces surface defects, enabling the solar cells to operate more efficiently and extending their lifespan. Consequently, the power conversion efficiency of the solar cells increased from 13.6% to 15.3%, demonstrating stability by maintaining 83% of their performance for 15 days.

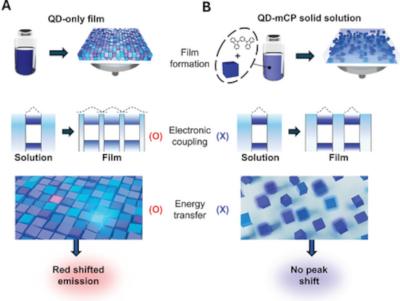

Decoupling of colloidal perovskite QDs could enable efficient deep-blue LEDs

Metal halide perovskite light-emitting diodes (PeLEDs) that emit deep-blue color with high efficiency have not yet been fully achieved and become more difficult in the thin film of confined perovskite colloidal quantum dots (PeQDs) due to particle interaction. Recently, researchers from Seoul National University and University of Toronto demonstrated that electronic coupling and energy transfer in PeQDs induce redshift in the emission by PeQD film, and consequently hinder deep-blue emission.

Scheme illustrating QD-QD interaction related to emission spectrum shifts in the A) QD-only film and B) QD-mCP solid solution. Image credit: Advanced Materials

To achieve deep-blue emission by avoiding electronic coupling and energy transfer, a QD-in-organic solid solution was introduced, to physically separate the QDs in the film. This physical separation of QDs reduces the interaction between them yielding a blueshift of ≈7 nm in the emission spectrum.

Pagination

- Page 1

- Next page