IIT Guwahati team uses perovskites for mercury detection in cells and environment

Researchers from the Indian Institute of Technology Guwahati have reportedly developed a perovskite-based approach to detecting harmful metals like mercury in living cells and the environment.

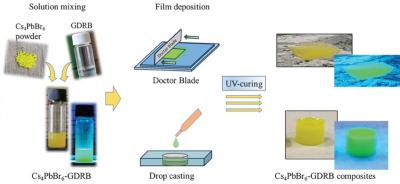

The team relied on perovskites' unique interaction with light, which enables them to serve as fluorescent probes inside living cells. However, their quick degradation in water has previously limited their applications. To address this, the researchers encapsulated the perovskite nanocrystals in silica and polymer coatings, significantly enhancing their stability and luminescent intensity in water. This modification ensures the nanocrystals maintain their functionality over extended periods, making them highly effective for practical use.