Radiation detectors, which convert radiation into measurable light signals, currently come in fixed shapes like blocks or cylinders because they are made by growing crystals at extremely high temperatures – around 1700 °C. These rigid shapes make it difficult to measure radiation doses accurately around irregularly shaped tumors or in tight spaces. Previous attempts to create detectors in custom shapes have focused on plastic materials that can be easily molded, but these plastic detectors perform poorly because they lack the heavy elements needed to efficiently capture radiation. Scientists have tried mixing metal particles into plastics to improve their detection ability, but this often results in uneven distribution of the particles and poor overall performance.

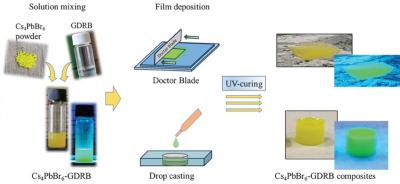

A research team from several institutions in Italy and Switzerland has now developed a new approach using stereolithography (SLA), a precise form of 3D printing that builds objects by hardening light-sensitive liquid materials layer by layer. This marks the first successful use of SLA to fabricate 3D-printed scintillators, a breakthrough in radiation detection technology. The team mixed microscopic crystals of cesium lead bromide (Cs4PbBr6), a perovskite material, into a liquid resin that hardens when exposed to ultraviolet light. Perovskites have gained significant attention in recent years because they efficiently convert various forms of energy into light. Their crystal structure, which contains heavy elements like lead, makes them particularly effective at detecting radiation.

Getting this mixture right required careful engineering. Too little crystal material would make poor detectors, while too much would prevent the resin from hardening properly or block light from traveling through the material. Through systematic testing, the team found that adding crystal particles making up 2.5% of the mixture's weight provided the best balance of properties.

The material showed several promising characteristics. The hardened resin shielded the crystals from moisture, significantly enhancing their durability compared to bare crystals. The material also responds extremely quickly to radiation, converting it to visible green light in one billionth of a second – a critical feature for advanced medical imaging techniques that require precise timing to create accurate 3D images.

Using a commercial SLA printer, the team created detectors in various complex shapes that would be impossible to achieve with traditional crystal-growing methods. The printing process takes less than two hours and is relatively inexpensive compared to growing crystal detectors. The researchers successfully printed intricate patterns while maintaining uniform distribution of the crystal particles throughout the material.

Currently, the material produces about 10% as much light as commercial detectors when struck by radiation, primarily due to the size and dispersion of the crystal particles in the resin. However, for applications where detector shape is more important than maximum light output, this trade-off may be acceptable. The ability to create precisely shaped detectors could enable new approaches to radiation therapy monitoring, where measuring radiation patterns in complex 3D shapes around tumors is more crucial than detecting very weak radiation.

The research team is now working to improve light output by developing methods to create smaller crystal particles and distribute them more evenly throughout the resin. They are also exploring different crystal compositions and investigating techniques to print larger and more complex detector shapes. With further refinements, this technology could revolutionize radiation therapy by enabling more precise and personalized treatments. The combination of custom shapes and fast response times might also find applications in particle physics research, where detecting radiation patterns in complex geometries is often crucial.