Researchers from the University of Cambridge, Lawrence Berkeley National Laboratory and the University of California, Berkeley, have developed a novel way to make hydrocarbons – powered solely by the sun.

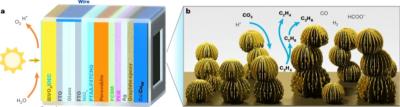

a) Architecture of the tandem PEC device. b) A schematic illustration of the nanoporous electrode. Image credit: Nature Catalysis

The device they developed combines a light absorbing ‘leaf’ made from a perovskite solar cell, with a copper nanoflower catalyst, to convert carbon dioxide into useful molecules. Unlike most metal catalysts, which can only convert CO₂ into single-carbon molecules, the copper flowers enable the formation of more complex hydrocarbons with two carbon atoms, such as ethane and ethylene — key building blocks for liquid fuels, chemicals and plastics.

Almost all hydrocarbons currently stem from fossil fuels, but the method developed by the team results in clean chemicals and fuels made from CO2, water and glycerol – a common organic compound – without any additional carbon emissions. The results are reported in the journal Nature Catalysis.

The study builds on the team’s earlier work on artificial leaves, which take their inspiration from photosynthesis: the process by which plants convert sunlight into food. “We wanted to go beyond basic carbon dioxide reduction and produce more complex hydrocarbons, but that requires significantly more energy,” said Dr. Virgil Andrei from Cambridge, the study’s lead author.

By coupling a perovskite light absorber with the copper nanoflower catalyst, the team was able to produce more complex hydrocarbons. To further improve efficiency and overcome the energy limits of splitting water, the team added silicon nanowire electrodes that can oxidize glycerol instead. This new platform produces hydrocarbons much more effectively — 200 times better than earlier systems for splitting water and carbon dioxide.

The reaction not only boosts CO₂ reduction performance, but also produces high-value chemicals such as glycerate, lactate, and formate, which have applications in pharmaceuticals, cosmetics, and chemical synthesis.

“Glycerol is typically considered waste, but here it plays a crucial role in improving the reaction rate,” said Andrei. “This demonstrates we can apply our platform to a wide range of chemical processes beyond just waste conversion. By carefully designing the catalyst’s surface area, we can influence what products we generate, making the process more selective.”

While current CO₂-to-hydrocarbon selectivity remains around 10%, the researchers are optimistic about improving catalyst design to increase efficiency. The team envisions applying their platform to even more complex organic reactions, opening doors for innovation in sustainable chemical production. With continued improvements, this research could accelerate the transition to a circular, carbon-neutral economy.

“This project is an excellent example of how global research partnerships can lead to impactful scientific advancements,” said Andrei. “By combining expertise from Cambridge and Berkeley, we’ve developed a system that may reshape the way we produce fuels and valuable chemicals sustainably.”