Researchers from University of Electronic Science and Technology of China (UESTC), CNRS, Guangzhou University and China Jiliang University have developed a slot-die coating strategy based on pyrrodiazole (PZ) additives in the perovskite precursor solution to simultaneously immobilize lead iodide and formamidinium iodide.

Image from: Nature Communications

This approach is meant to enhance wet film stability by suppressing colloidal aggregation, retards the crystal growth process, and ensures a consistent growth rate across the films. These effects can promote the formation of large, monolithic grains, enabling large-area perovskite films with homogeneous structure, excellent uniformity, and low defect density under ambient conditions. Using this strategy, the scientists achieved 10 cm × 10 cm inverted perovskite solar modules with a certified efficiency of 20.3% and retained 94% of initial efficiency after 1,000 h in standard testing, along with good working stability and excellent application demonstration, showcasing its great potential for industrialization.

Both lead iodide (PbI2) and formamidinium iodide (FAI) benefitted from the PZ immobilization strategy, enabling the formation of “high-quality” perovskite films for the cells. “The immobilization effect, driven by the formation of Lewis acid-base pairs (PZ-PbI2) and hydrogen bonds (PZ-FAI), not only improves the colloidal size distribution uniformity in the perovskite precursor solution but also enhances the stability of the wet film by inhibiting colloid agglomeration,” the group explained.

The cell stack was designed with a transparent fluorine-doped tin oxide (FTO) coated glass substrate, a sputtered nickel(II) oxide (NiOx) film, the methyl-substituted carbazole (Me-4PACz) layer, perovskite, buckminsterfullerene (C60) electron transport layer (ETL), a bathocuproine (BCP) buffer layer, copper (Cu) contact.

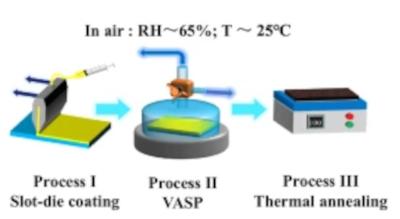

The Me-4PACZ film was coated on the NiOx film surface with blade coating in air. “After that, the prepared perovskite precursor solution with different concentrations of additives were deposited in air by slot-die coating technology,” said the team.

Real-time characterization revealed that “this approach not only retards the crystal growth process but also ensures consistent crystallization rates between the upper and lower layers of the perovskite film,” the researchers explained. The process facilitates formation of large, monolithic grains with “excellent uniformity.”

The inverted perovskite solar mini modules in the experiment measured 10 cm × 10 cm. Each had 11 cells connected in series. It is worth noting, stated the researchers, that the P1, P2, and P3 scribing of the series-connected modules, had P1 and P3 dividing the module sub-cells, with P2 connecting the sub-cells.

Further tests revealed that, in modules with an aperture area of 56.5 cm2, PZ improved module efficiency from 18.2% to 21.5%, while PZ-I and PZ-II either had negligible effects (17.9%) or reduced efficiency (17.0%).

This study provides a promising strategy for the industrial-scale production of large-area inverted perovskite solar modules, as well as effective guidance for large-scale commercialization of PSCs.