Fuel cells are a hoped to be a key future energy technology for achieving renewable energy sources that are eco-friendly and low-cost. In particular, solid oxide fuel cells composed of ceramic materials are gaining increasing amounts of attention for their ability to directly convert various forms of fuel such as biomass, LNG, and LPG to electric energy. Researchers at KAIST have relied on pervoskite materials to develop a new technique to improve the chemical stability of electrode materials that can extend their lifespan by employing minimal amounts of metals.

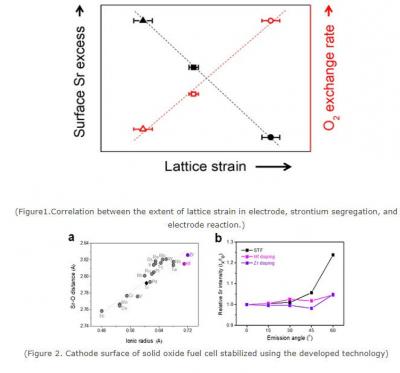

The core factor that determines the performance of solid oxide fuel cells is the cathode at which the reduction reaction of oxygen takes place. Conventionally, perovskite structure oxides (ABO3) are used in cathodes. However, despite the high performance of perovskite oxides at initial operation, performance degrades with time, limiting their long-term use. In particular, the condition of a high-temperature oxidation state required for cathode operation leads to a surface segregation phenomenon in which second phases such as strontium oxide (SrOx) accumulate on the surface of oxides, resulting in a decrease in electrode performance. The detailed mechanism of this phenomenon and a way to effectively inhibit it has not been suggested.

The team said "this technology can be implemented by adding a small amount of metal atoms during material synthesis, without any additional process". The researchers are hoping that this new technology can be useful in developing highly-durable perovskite oxide electrode in the future.