Australian National University (ANU) researchers have managed to push forward the efficiency of solar-to-hydrogen production that bypasses electrolysers and avoids AC/DC power conversion and transmission losses. They have recently managed to reach 17.6% efficiency, achieved with perovskite-silicon tandem absorbers, and they say their process is open to further refinement that could see clean hydrogen production become cost competitive with other fuels, including brown hydrogen and gas, more quickly than expected.

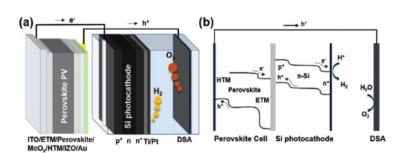

Perovskite-Si dual-absorber tandem PEC cell for self-driven water splitting. a) Schematic showing a perovskite solar cell wired to a Si photo-cathode in tandem, and a DSA anode. b) A representative general energy band diagram. Image: ANU

Perovskite-Si dual-absorber tandem PEC cell for self-driven water splitting. a) Schematic showing a perovskite solar cell wired to a Si photo-cathode in tandem, and a DSA anode. b) A representative general energy band diagram. Image: ANU

Australian National University (ANU) researchers, in a newly-released study lead by Dr. Siva Krishna Karuturi and Dr. Heping Shen, state that although PV modules have become a commercially viable method large-scale renewable energy generation, 'Achieving global renewable energy transition further relies on addressing the intermittency of solar electricity through the development of transportable energy storage means.'

In 2009 the US Department of Energy, intent on providing a framework for viability of green hydrogen production set targets for PEC water-splitting efficiency of 20% by 2020, with 25% efficiency as the ultimate goal.

Although some semiconductors have demonstrated solar-to-hydrogen (STH) efficiencies of up to 19%, their high cost of materials has limited their application; at the same time, STH efficiencies achieved with inexpensive semiconductor materials have remained below 10%, and the materials themselves have been vulnerable to degradation.

The ANU researchers' pairing of a buried p-n junction silicon/titanium/platinum photocathode with a semitransparent perovskite solar cell, is the first deployment of cheaper materials to achieve anywhere near 20% efficiency.

'As revealed by our modeling results, the proof-of-concept demonstration offers immense opportunities to further improve the efficiency and reduce costs through optimization of the performances of the individual components and replacement of precious catalysts with abundant materials,' writes Karuturi.

He describes his team's solution as 'An elegant and potentially economical route to storing solar power.'

The PEC process, in bypassing the electrolyser step of envisaged large-scale green hydrogen production, and its attendant limiting cost factor, shows the ANU team's work to be a potential game changer in the race to produce commercially viable hydrogen.