Recently, a University of Louisville team of researchers used nanoparticle inks by Sofab Inks (a U of Louisville spinout) to create PSCs with ~20% PCE on flexible substrates. Their study addresses the solvent scope and perovskite compatibility of acetate-stabilized yttrium-doped SnO2 (Y:SnO2) dispersions.

Tin oxide (SnO2) stands out as a compelling electron transport material (ETM) for perovskite solar cells (PSCs), boasting exceptional optoelectronic properties, coupled with low-temperature solution processability, cost-effectiveness, and remarkable stability. However, the widespread application of SnO2 has been hindered by solvent incompatibilities, limiting its use to devices where it is deposited beneath the perovskite layer. To unlock the full potential of SnO2 and expand its use across various device structures, including inverted PSCs and tandem devices, innovative deposition strategies will need to be developed. These advancements could pave the way for more efficient and versatile solar cell designs, pushing the field of photovoltaics forward.

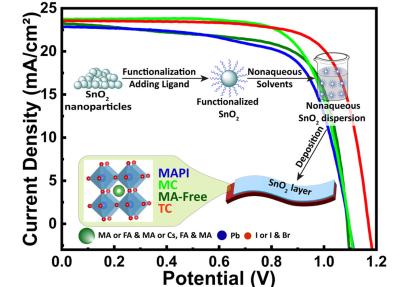

The scientists showed that dispersions in several lower alcohols and select polar aprotic solvents can be directly deposited on perovskite using scalable and low-temperature processes. In addition, they are compatible with various perovskite formulations, including those with mixed cations and mixed anions.

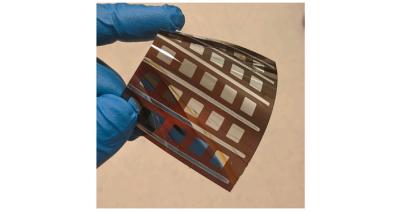

A stable dispersion of pre-synthesized Y:SnO2 nanoparticles was prepared by functionalization with acetate ligands. The Y:SnO2-A nanoparticle dispersions were then directly deposited via blade coating onto four different lead halide perovskite layers and a series of inverted flexible PSCs (f-PSC) on ITO-coated PET substrate were fabricated. The performance of these f-PSCs achieved champion power conversion efficiencies (PCEs) of 16.90%, 18.68%, 17.71%, and 20.41%, and average PCEs of 15.27%, 16.63%, 16.13%, and 19.02% for MAPI, Mixed Cation, TMA-free, and Triple Cation devices, respectively. The unencapsulated Triple Cation devices retained 90% of their initial average PCE after 600 h under continuous light illumination in an atmosphere-controlled box at 10% humidity and a temperature of 35 ± 5°C.

The study expands the applicability of SnO2 as a solution-processible and cost-effective ETM as an alternative to fullerene-based organic ETMs and serves as a guide for its use in PSCs and tandem devices. In this research, the SnO2 ETM material was provided by Sofab Inks. Click here to learn more about the company's novel ETL and HTL Tin Oxide materials!