Researchers from the University of Minnesota Twin Cities-led, University of Wisconsin–Madison and Pacific Northwest National Laboratory have developed a new method for making thin films of perovskite oxide semiconductors, a class of “smart” materials with unique properties that can change in response to stimuli like light, magnetic fields, or electric fields.

Their work could allow researchers to harness these properties and even combine them with other emerging nano-scale materials to make better devices such as sensors, smart textiles, and flexible electronics.

Producing materials in thin-film form makes them easier to integrate into smaller components for electronic devices. Many thin films are made using a technique called epitaxy, which consists of placing atoms of a material on a substrate, or a template of sorts, to create a thin sheet of material, one atomic layer at a time. However, most thin films created via epitaxy are “stuck” on their host substrate, limiting their uses. If the thin film is detached from the substrate to become a freestanding membrane, it becomes much more functional.

The University of Minnesota-led team has found a new way to successfully create a membrane of a particular metal oxide—strontium titanate—and their method circumvents several issues that have burdened the synthesis of freestanding metal oxide films in the past.

“We have created a process where we can make a freestanding membrane of virtually any oxide material, exfoliate it, and then transfer it onto any subject of interest we want,” said Bharat Jalan, a senior author on the paper and a professor and Shell Chair in the University of Minnesota Department of Chemical Engineering and Materials Science. “Now, we can benefit from the functionality of these materials by combining them with other nano-scale materials, which would enable a wide range of highly functional, highly efficient devices.”

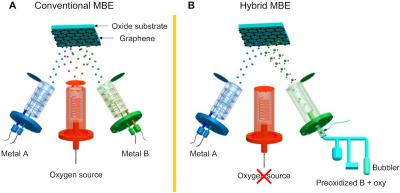

Making freestanding membranes of “smart” oxide materials is challenging because the atoms are bonded in all three dimensions, unlike in a two-dimensional material, such as graphene. One method of making membranes in oxide materials is using a technique called remote epitaxy, which uses a layer of graphene as an intermediary between the substrate and the thin-film material.

This approach allows the thin-film oxide material to form a thin film and be peeled off, like a piece of tape, from the substrate, creating a freestanding membrane. However, the biggest barrier to using this method with metal oxides is that the oxygen in the material oxidizes the graphene on contact, ruining the sample.

Using hybrid molecular beam epitaxy, a technique pioneered by Jalan’s lab at the University of Minnesota, the researchers were able to get around this issue by using titanium that was already bonded to oxygen. Plus, their method allows for automatic stoichiometric control, meaning they can automatically control the composition.

“We showed for the first time, and conclusively by doing several experiments, that we have a new method which allows us to make complex oxide while ensuring that graphene is not oxidized. That's a major milestone in synthesis science,” Jalan said. “And, we now have a way to make these complex oxide membranes with an automatic stoichiometric control. No one has been able to do that.”

“These complex oxides are a broad class of materials that have a lot of really important innate functions to them,” said Koester, also a senior author of the study and the director of the Minnesota Nano Center at the University of Minnesota Twin Cities. “Now, we can think about using them to make extremely small transistors for electronic devices, and in a wide array of other applications including flexible sensors, smart textiles, and non-volatile memories.”