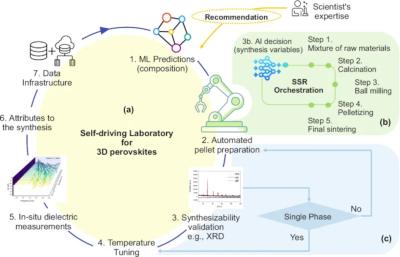

Researchers from Queen Mary University of London and QinetiQ could pave the way for faster discovery of novel perovskite materials with desirable properties for applications in wireless communication and biosensors. The recent research introduces an automated platform for rapid sintering and dielectric characterization of perovskite solid solutions. This innovative approach integrates machine learning (ML) for material screening with robotic synthesis and high-throughput characterization.

The scientists stated that while accelerating perovskite solid solution discovery and sustainable synthesis is crucial for addressing challenges in wireless communication and biosensors, the vast array of chemical compositions and their dependence on factors such as crystal structure and sintering temperature require time-consuming manual processes. To overcome these constraints, they introduced an automated materials discovery approach encompassing machine learning (ML) assisted material screening, robotic synthesis, and high-throughput characterization.

Their proposed platform for rapid sintering and dielectric analysis streamlines the characterization of perovskites and the discovery of disordered materials. The setup has been successfully validated, demonstrating processing materials within minutes, in contrast to conventional procedures that can take hours or days.

Following setup validation with established samples, the team showcases synthesizing single-phase solid solutions within the barium family, such as (BaxSr1-x)CeO3, identified through ML-guided chemistry.

“The traditional process for discovering new perovskite materials is time-consuming and relies heavily on manual experimentation,” explains Mojan Omidvar, PhD student at Queen Mary University of London. “Our automated platform streamlines this process significantly, allowing us to explore a wider range of compositions and identify promising candidates in a matter of minutes.”

The new platform drastically reduces processing times compared to conventional methods. Material sintering, which can take hours using traditional techniques, is completed within minutes using the new platform. It also eliminates the need for manual steps such as sample preparation and reheating for characterization, further streamlining the workflow and reduces measurement errors associated with traditional techniques. On top of that, the integration of ML allows the platform to learn from experimental outcomes and guide future explorations, accelerating the discovery process.

Professor Hao highlights the broader significance of this research: “This automated platform represents a significant step forward in the field of materials discovery. We hope it would speed up the development of new perovskite materials for various applications, from next-generation wireless communication systems to advanced biosensors.”