Perovskite Solar - Page 4

Researchers design multifunctional SnSO oxidant for efficient perovskite solar cells

Perovskite solar cells (PSCs) that incorporate a 2D/3D perovskite layer tend to demonstrate enhanced stability compared to that of their purely 3D counterparts, possibly thanks to the superior chemical stability of the 2D perovskite layer. However, the poor electrical properties of the 2D perovskite layer also limit further improvement of device performance. Moreover, the most effective hole transport layer (HTL) in 2D/3D PSCs, lithium bis(trifluoromethylsulfonyl)imide (Li-TFSI)-doped 2,2′,7,7′-tetrakis(N,N-di(4-methoxyphenyl)amino)-9,9-spirobifluorene (spiro-OMeTAD), usually needs prolonged exposure to air to improve its conductivity, which to some extent increases the risk of water/oxygen infiltrating into the perovskite layer, leading to the degradation of the perovskite active layer.

Researchers at China's Henan University and Chinese Academy of Sciences (CAS) have developed a multifunctional dopant, tin oxysulfide (SnSO) in the spiro-OMeTAD layer, to improve the efficiency and stability simultaneously.

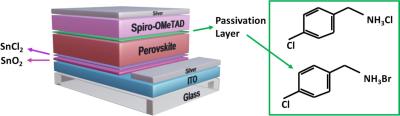

Researchers develop passivation strategy for chloride-iodide perovskites with chlorobenzylammonium halides

Researchers from Australia’s University of New South Wales (UNSW) Sydney have developed a defects passivation strategy for chloride-iodide-based perovskite. The team targeted the hard-to-avoid local defects in chloride-iodide-based perovskites, using two organic halide passivators named 4-chlorobenzylammonium chloride and 4-chlorobenzylammonium bromide.

The scientists passivate both the surface and bulk of the perovskite thin film. The surface of the perovskite thin film is passivated with the bulky organic benzylammonium cations. The bulk of the perovskite thin film is passivated with the diffusion of chlorine or bromine.

Semi-Transparent Perovskite Solar Cells - Guest Post by Ossila's Dr. Mary O'Kane

Semi-transparent solar cells are appealing for many different applications such as building-integrated photovoltaics (BIPVs), tandem solar cells and in wearable electronics. Perovskites could be ideal for semi-transparent applications as they are versatile and easy to optimize.

Semi-transparent perovskite solar cells (ST-PSCs) must try to maximize efficiency and transparency. Methods such as bandgap engineering, thinning perovskite layers, and creating discontinuous structures are being developed to improve their performance. However, challenges still remain with ST-PSC development, such as phase stability and defect management.

Researchers report blade-coated perovskite/silicon tandem solar cell with 31.2% efficiency

Researchers from King Abdullah University of Science and Technology (KAUST) and Helmholtz-Zentrum Berlin (HZB) have developed a perovskite-silicon tandem solar cell that achieves efficient charge extraction and interface passivation. The team improved the performance of blade-coated tandems by introducing 2D perovskite layers at the bottom interface.

Image credit: Joule

These modifications enhanced the blade-coated tandem performance to a certified PCE of 31.2%, owing to efficient charge extraction and interface passivation. This work demonstrates the efficiency potential for scalable ink-based fabrication, emphasizing stability and manufacturability, which are crucial for the widespread adoption and commercial success of this promising photovoltaic (PV) technology.

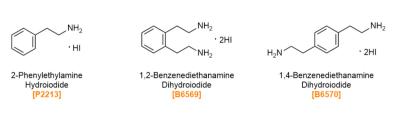

TCI launches Phenylethylamine Hydroiodides materials to increase the stability of perovskite solar panels

Tokyo Chemical Industry (TCI), a global supplier of laboratory chemicals and specialty materials, is now offering Phenylethylamine Hydroiodides materials, used for surface treatment of perovskite layers in solar panels. These materials improve the stability of the solar panels.

Research has shown that by applying the Phenylethylamine Hydroiodides materials, one can expect improved stability of over 90%. In one research, the 1,2-Benzenediethanamine Dihydroiodide was applied to a perovskite PV device (FTO/TiO2/SnO2/perovskite/Amine Iodide/Spiro-OMeTAD/Au), and achieved an increase in stability of over 90% after 1,100 hours. See here for more info.

Renesola Henan begins PV plant construction, plans to establish a 2 GW perovskite solar modules production line as a next step

Global PV project developer and panel manufacturer, Renesola, recently held a groundbreaking ceremony for its 3GW PV module production factory in Longan District, Anyang City, Henan Province. The total investment for the project is approximately 3 billion yuan (almost USD$422 million).

The first phase of the project will establish a 3GW photovoltaic module production line, along with essential production equipment such as frames, brackets, and welding strips, with the goal of creating a comprehensive photovoltaic industry chain. While this plant is not focused on perovskite-based PV, it is important to note that the second phase of ReneSola's Anyang base plans to establish a 2 GW Perovskite solar modules production line, covering an area of approximately 40,000 square meters.

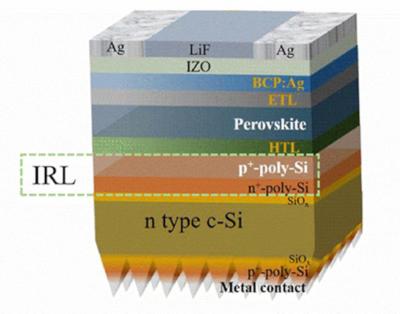

Researchers develop optimized polysilicon tunneling intermediate recombination layer for high-efficiency perovskite/TOPCon tandem solar cells

Researchers at Chinese Academy of Sciences (CAS) have fabricated an intermediate recombination layer (IRL) featuring a heavily doped boron/phosphorus polysilicon tunneling junction, with tunnel oxide passivated contact (TOPCon) silicon cells serving as the bottom cell for perovskite/TOPCon tandem solar cells (TSCs).

In perovskite/silicon TSCs, the IRL is an important structure electrically connecting the top-side perovskite and bottom-side silicon sub-cells, significantly influencing the overall device performance. The traditional IRL often uses ITO materials to ensure high transmittance and good electrical properties, which, however, usually leads to issues such as sputtering damage and low temperature process limitations.

BOE announces its first 1.2m*2.4m perovskite solar module

Hefei BOE Solar Technology has announced the successful production of the first 1.2m*2.4m perovskite solar module (in a line that was said to be completed in 38 days).

BOE said that its three major R&D platforms have all entered the first-class echelon of the industry, realized independent debugging of fully automatic intelligent production lines, and mastered the dry coating process. Currently, its glove box champion efficiency is 25.6%, and the experimental line champion efficiency is 20.63%.

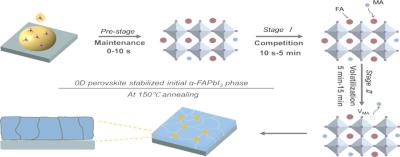

Novel 0D strategy offers a promising path toward more stable PSCs

While formamidinium lead triiodide (FAPbI3) perovskite can be used to create highly efficient perovskite solar cells (PSCs), the thermodynamically unstable α-phase poses a challenge to device long-term stability. Thermal annealing is essential for producing high-quality polycrystalline films that stabilize the α-FAPbI3 phase, but it also induces partial decomposition of FAPbI3 into PbI2, leading to extra phase instability of FAPbI3 films.

Researchers from the University of Science and Technology of China, Chinese Academy of Sciences, NingboTech University and Nankai University have developed a zero dimensional (0D) perovskite-decorated strategy to enhance the intrinsic stability of FAPbI3 film by stabilization of the initially formed α-FAPbI3 phase.

Perovskite solar cells gain improved stability through atomic layer deposition of tin oxide

Researchers from City University of Hong Kong, National Renewable Energy Laboratory (NREL) and Imperial College London have improved the long-term stability of perovskite solar cells with an atomic-layer deposition (ALD) method that replaces the fullerene electron transport layer with tin oxide.

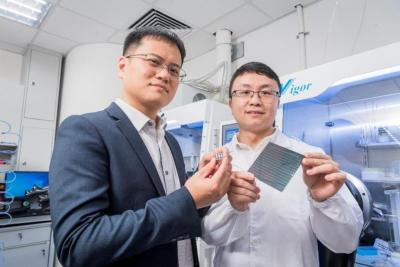

Professor Zhu Zonglong (left) and Dr Gao Danpeng of City University of Hong Kong hold their innovative solar cells. Image credit: Eurekalert

The team started by depositing the perovskite and the hole-transporter layer in a single step. Then, they used ALD to create an oxygen-deficient tin oxide layer to reduce the band offset to a thicker, overgrown layer of normal tin oxide. Solar cells had a power conversion efficiency of more than 25%, and they retained more than 95% of efficiency after 2000 hours of maximum power point operations at 65°C.

Pagination

- Previous page

- Page 4

- Next page