This is a sponsored post by MBRAUN

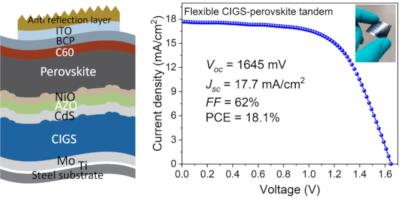

In the quest for cleaner, more efficient energy sources, perovskite solar cells have proven to be a promising prospect. Their exceptional efficiency, low-cost production and versatility make them a promising candidate for revolutionizing the renewable energy. However, the road to mass adoption faces hurdles, one of which is the need for precise and efficient manufacturing processes. Here's where vacuum evaporation tools shine as indispensable assets in the production of perovskite solar cells.

Precision Engineering for Optimal Performance

At the heart of perovskite solar cell fabrication lies the deposition of thin films with utmost precision under highly controlled conditions. MBRAUN evaporation tools from the PEROvap series offer unparalleled control over the deposition process, ensuring the uniformity and consistency essential to maximize solar cell efficiency. Addressing the volatility of most used Perovskite materials PEROvap systems are designed to control the temperature of the chamber, the substrate holder, the sources and the quartz crystals precisely from -40°C up to room. This avoids unwanted re-evaporation of already deposited materials and stabilizes the overall evaporation process. By vaporizing the material under vacuum conditions and depositing it onto the substrate, PEROvaps also eliminate impurities and defects that could affect performance, resulting in high-quality perovskite films with superior optoelectronic properties.

Learn more about the vacuum coating solutions from MBRAUN