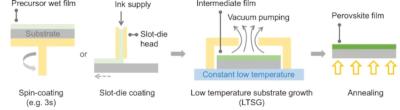

Researchers from the Chinese Academy of Sciences (CAS) posit that the efficiency and stability of perovskite modules are mainly limited by the quality of scalable perovskite films and sub-cells’ lateral contact. So, in their recent work, they addressed this by reporting constant low temperature substrates to regulate the growth of perovskite intermediate films to slow down the crystallization process. This is meant to assist in obtaining high-quality homogeneous perovskite films in large scale size, which avoid the effect of the ambient temperature on the film quality.

Schematic diagram of the fabrication process of perovskite films using low-temperature substrate growth (LTSG). Image from Nature Communications

In addition, a scribing step named P1.5 was added before the top function layers deposition, so the diffusion barrier layer can be formed “naturally” at the interconnection interface without introducing any additional materials, which alleviates the diffusion degradation process.

As a result, the team's inverted perovskite devices exhibited a very small efficiency loss with area expansion comparable to other photovoltaic devices (for example, Cadmium Telluride), the perovskite module (aperture area 14.61 cm2) showed a certified quasi-steady-state power conversion efficiency of 22.73%, and the module maintained over 90% of its initial efficiency after 1000 hours of continuous operation under illumination.