Researchers from the University of Warsaw and the Fraunhofer Institute for Solar Energy Systems ISE have examined the question of whether or not nano-scale surface texturing, used on some silicon cells, can be applied to perovskite cells instead of more commonly used planar magnesium fluoride anti-reflection coatings.

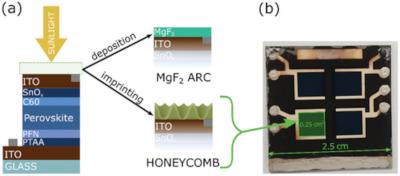

a) the scheme of the perovskite solar cell sample before any top surface modification and after the application of either MgF2 layer or honeycomb texture application, b) device photography with four active cell areas after imprinting the honeycomb texture. Image from Advanced Materials and Interfaces

“To minimize losses, silicon cells are typically etched with corrosive chemical agents, a process that creates microscopic pyramid pattern on the surface, effectively reducing reflection,” said the scientists. “Unfortunately, perovskites are sensitive to many chemical substances, which is why less effective planar anti-reflective coatings [planar MgF2] applied through less-invasive sputtering have been employed so far.”

Instead, the team tried ‘thermally assisted UV roller nano-imprint lithography’, using a roller with defined surface structures to press a suitable pattern into a thin coating on top of the perovskite cell layers – in this case a coating of the epoxy etch-resist SU-8 2002. The coating was required as the underlying perovskite cell was unlikely to survive imprint lithography on its own.

This particular from of nano-imprint lithography “meets the criteria of reliable repeatability of high aspect ratio structures with high throughput and long stamp lifetimes”, according to Warsaw University. “We showed that this process chain was harmless enough to not deteriorate the performance. To the best of our knowledge such or a similar structure has never been directly applied to a perovskite solar cell.”

It is also applicable to macro-scale surfaces – up to 100cm2.

“Until now, scientists applied similar anti-reflective structures as separately prepared layers, which were transferred in another process that was inevitably small-scale and susceptible to damaging the active layer,” said the researchers.

The results show that the applied honeycomb pattern reduces the solar-weighted reflectance from 13.6% to 2.7%, which enhances the current density of the unmodified cell by 2.1 mA cm−2, outperforming the commonly used planar MgF2 antireflective coating by 0.5 mA cm−2. The experimental results are combined with optical modeling to find optimized structures and predict the optical behavior within a solar module. The process used within this work can be transferred to perovskite-silicon tandem solar cells, providing a promising pathway for the reflection reduction in future devices.