Perovskite Solar - Page 7

Halocell and First Graphene enter agreement to supply graphene for perovskite solar cells

Halocell Energy has entered into an agreement with First Graphene, which will supply graphene for the manufacture of perovskite solar cells.

The initial two-year agreement will result in First Graphene providing its PureGRAPH material to Halocell for use as a high-performing coating for perovskite solar cells. By incorporating PureGRAPH into its products, Halocell Energy hopes to expedite its manufacturing process and enhance light absorbing performance, which will enable the company to scale up commercial production to meet demand.

Fraunhofer team develops scalable perovskite/silicon tandem cell with 31.6% efficiency

Scientists at the Fraunhofer Institute for Solar Energy Systems ISE have developed a perovskite silicon tandem solar cell with 31.6% efficiency.

The new 1 cm² solar cell is special in that the perovskite layer of the top cell was deposited on an industrially textured silicon heterojunction solar cell using a hybrid manufacturing route. The successful use of textured standard silicon solar cells and the uniform application of the perovskite layer on the texturized surface are important prerequisites for the industrial production of perovskite silicon tandem solar cells.

New EU-funded project aims to develop efficient, stable large-area perovskite solar module

An EU-funded Laperitivo project was launched earlier this month, focused on manufacturing large-area stable perovskite solar modules. Laperitivo stands for “large-area perovskite solar module manufacturing with high efficiency, long-term stability, and low environmental impact.” The project aims to achieve 22% efficiency for 900 cm² opaque panels and 20% for semi-transparent modules with more than 95% bifaciality.

The team will focus, among other things, on solving scalability challenges, to promote large-scale mass production with minimized losses. The abstract of the project’s EU funding paper also states that: “Indoor and outdoor field tests will be performed to monitor module reliability. Safety, circularity, and sustainability will be assessed to demonstrate products with minimized environmental impact.”

Perovskia Solar raises $2.4 million to enable customized solar-cells

Perovskia Solar, a spin-off from the Swiss Federal Laboratories for Materials Science and Technology (Empa), has secured USD$2.4 million in funding from a global coalition of angels and early-stage funds, and successfully obtained 10+ Internet-of-Things (IoT) industry leaders as clients. The startup has introduced the first ready-to-adopt perovskite solar cells on the market for edge devices and is scaling up its Swiss manufacturing capacity.

Perovskia Solar is a Swiss cleantech startup that develops highly efficient, custom-designed solar cells for IoT and consumer electronic devices. These cells harness ambient light to power the next generation of self-sustaining devices, drastically reducing reliance on traditional batteries and minimizing waste. The company's vision is to integrate a solar cell into every device, enabling clients to launch breakthrough products with superior end-user experiences while tackling global environmental challenges.

The Washington State Department of Commerce grants funding for development of high-efficiency wide-bandgap perovskite-based solar cell

The Washington State Department of Commerce (DOC) announced a $37 million investment into 46 clean energy projects throughout the state.

The programs will be funded by the Washington Climate Commitment Act (and additional state funding), with $14 million going towards the “Research, Development and Demonstration” program, which awards “projects fund multiple new and developing technologies, ranging from low-head turbines to create hydropower, to several different carbon capture technologies, to low-carbon concrete products.”

Wuxi UtmoLight to build a 1GW perovskite module factory in Shandong, China

Reports suggest that a number of renewable-related projects have recently been signed in Shanghai, China, including a 1GW perovskite module factory.

The perovskite solar module factory will be initiated by Wuxi UtmoLight Technology (UtmoLight), a China-based technology development company working towards perovskite commercialization, with a total investment of 1.5 billion yuan ( around USD$212,221,000), The new facility will be located in Heze City, Shandong Province.

'PeroCycle' project to develop an industrially viable recycling process for perovskite solar modules

Researchers at the Centre for Solar Energy and Hydrogen Research Baden-Württemberg (Zentrum für Sonnenenergie- und Wasserstoff-Forschung - ZSW) in Germany are working with two industry partners to investigate how end-of-life thin-film solar modules can be reused. The partners in the new 'PeroCycle' project aim to develop an industrially viable recycling process for perovskite solar modules in four steps.

ZSW's two partners are Solaveni of Bönen and Solar Materials of Magdeburg. Solaveni brings expertise from the chemical processing of perovskite materials while Solar Materials specializes in the physical separation of composite materials without the use of chemicals. The scientists at the ZSW can draw on over 30 years of experience with thin-film solar modules and over ten years of materials research on perovskite solar cells and modules. The German Federal Environmental Foundation (Deutsche Bundesstiftung Umwelt - DBU) is funding the joint project.

Researchers develop novel HTL for efficient and stable perovskite solar cells

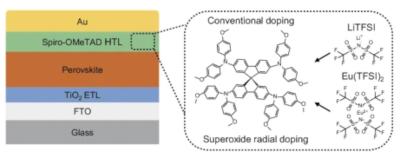

Researchers from China's Northwestern Polytechnical University, The Hong Kong University of Science and Technology, and Spain's Technical University of Madrid have developed a new lithium-free doping strategy to fabricate spiro-OMeTAD-based hole transport layers (HTLs) for applications in perovskite solar cell. A PV device built with a lithium salt-doped HTL achieved an efficiency of 25.45%.

Schematic illustration of a n-i-p PSC with spiro-OMeTAD HTLs doped by LiTFSI or Eu(TFSI)2. Image from Nature Communications

The team's lithium-free doping strategy to fabricate a perovskite solar cell is based on a metal-free hole transport layer (HTL) made of spiro-OMeTAd that reportedly offers remarkable efficiency and stability levels. The research team explained that spiro-OMeTAD for perovskite cell applications is usually doped with a compound known as lithium bis(trifluoromethanesulfonyl)imide (LiTFSI) to enhance hole extraction and conductivity. This kind of doping, however, requires time-intensive air-oxidization for 24 hours, which reportedly represents an obstacle to the commercial production of perovskite PV devices.

Project aims to replace sensors’ batteries with perovskite solar cells

An NSW Smart Sensing Network Grand Challenge Fund project is hoping to eliminate the reliance of sensors on disposable batteries by testing the fast production of perovskite photovoltaic (PV) cells, in the hope of creating a more sustainable sensor power source. The NSW Smart Sensing Network, a consortium of eight leading universities across NSW and the ACT, is a not-for-profit innovation network that brings together universities, industry and government to translate world-class research into innovative smart sensing solutions that create value for NSW and beyond.

The Revolutionizing Indoor Sensor Power: Rapid Microwave Annealing for Ultra-low-cost Perovskite Solar Cells project is being led by Dr. Binesh Veettil, a Senior Lecturer in the School of Engineering at Macquarie University. “Perovskite cells offer continuous power, and are ideal for harvesting indoor light to power low-power sensors,” Dr. Veettil says. “They are cost-effective when mass manufactured and they are suitable for roll-to-roll manufacturing as they can be screen-printed, slot-die coated, or spray-painted. Unfortunately the lengthy annealing time required is a challenge to be addressed to enable their widespread adoption.”

Researchers fabricate flexible perovskite solar cells on polycarbonate films

Researchers from CHOSE (Centre for Hybrid and Organic Solar Energy) at Tor Vergata University of Rome, ENEA Frascati Research Centre, Fraunhofer FEP, University of Guilan and Halocell Europe have developed perovskite solar cells (PSCs) on polycarbonate films.

Despite polycarbonate's widespread use in many applications, poor chemical resistance and roughness have hindered its adoption as a substrate in solar cell technologies. These challenges were solved by developing a new planarizing layer over the polycarbonate films applied in liquid form using blade coating. This innovation reduced surface roughness from 1.46 µm to 23 nm, cut the water vapor transmission rate in half, and improved solvent resistance. As a result, the scientists achieved a power conversion efficiency of 13.0% for solar cells on polycarbonate substrates, with good durability and flexibility.

Pagination

- Previous page

- Page 7

- Next page