Imec is a leading independent nanoelectronics and digital technologies R&D hub with headquarters in Belgium.

Imec is a leading independent nanoelectronics and digital technologies R&D hub with headquarters in Belgium.

Imec leverages its state-of-the-art R&D infrastructure and its team of more than 5,500 employees and researchers for advanced semiconductor R&D activities, also including system scaling, silicon photonics, artificial intelligence, beyond 5G communications and sensing technologies.

Imec is involved in perovskite R&D, with work on perovskite LEDs, solar panelks and more. It is also a partner in Solliance.

Remisebosweg 1, Imec tower

Leuven

Belgium

Spotlight on: the TESTARE project

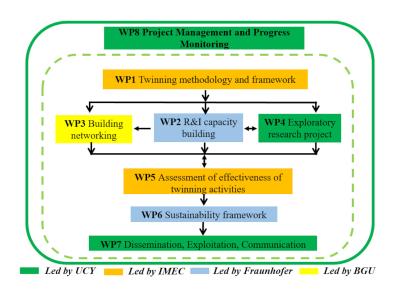

The TESTARE project is a 3-year Eu-funded project that commenced 1st January 2023 and running until 31 December 2025. TESTARE is a collaborative project of the Horizon Europe program under the category of Coordination and Support Actions (CSA) which target to improve cooperation among EU and associated countries to strengthen the European Research Area including, for example, standardization, dissemination, awareness-raising, communication and networking activities, policy dialogues, mutual learning or studies. The project aims to address major challenges in hybrid organic-inorganic perovskite-based photovoltaics (PV).

The project consortium comprises 4 organizations from 4 different countries: Cyprus, Belgium, Germany, and Israel. The project coordinator is University of Cyprus (UCY - Cyprus), while the project partners are Interuniversitair Micro-Electronica Centrum (IMEC - Belgium), Fraunhofer Gesellschaft zur Foerderung der angewandten Forschung e.V. (Fraunhofer – Germany) and Ben-Gurion University of the Negev (BGU - Israel). The project title is «Twinning for excellence in TEsting new generation PV: Long-term STAbility and field REliability».

Imec and partners test real-world outdoor stability of perovskite solar modules

Imec, partner in EnergyVille, in collaboration with the University of Cyprus, has demonstrated long-term outdoor stability of perovskite solar modules. Mini-modules of 4 cm2, developed at imec/EnergyVille, were comprehensively evaluated over two years in real-world conditions in Cyprus, with a remarkable power efficiency retention of 78% after one year, which current perovskite solar modules only retain for weeks. These promising findings are among the first real-world results to address the stability issues that currently hinder perovskite solar cells from commercialization.

Standard indoor testing in a controlled environment, which continuously mimics sun irradiation, only serves as a proxy for real-world performance. Environmental conditions, such as varying light, temperature and weather, impact cell performance. Despite this, only a handful of research groups have investigated outdoor performance of perovskite PV, focusing primarily on small cells rather than modules. Over the last two years, imec conducted a comprehensive study of the outdoor performance of their perovskite PV modules.

Researchers report electrically assisted amplified spontaneous emission in perovskite LEDs

Researchers at Imec have reported a metal halide perovskite LED (PeLED) stack that emits 1,000x more light “than state-of-the-art OLEDs”. The team developed a transparent PeLED architecture, that combines low optical losses with excellent current-injection properties.

In this work, the team showed that perovskite semiconductor optical amplifiers and injection lasers are within reach using this type of transparent PeLED.

Researchers develop perovskite solar panels with a thermally stable device stack

A research team led by Imec, that also included teams from Hasselt University and Kuwait University, has fabricated a perovskite solar module based on a scalable, stable device stack that can be processed with industry-compatible techniques, such as sputtering, evaporation, and slot-die coating.

The panel is based on 17%-efficient perovskite solar cells built with a p-i-n configuration, an electron transport layer made of nickel(II) oxide (NiOx), a perovskite layer deposited via slot-die coating, an electron transport layer made of buckminsterfullerene (C60) and lithium fluoride (LiF), a bathocuproine (BCP) buffer layer, and a copper (Cu) electrode.

Perovskite/CIGS tandem cell reaches 24.6% efficiency

imec, the world-leading research and innovation hub, recently presented an impressive thin-film tandem solar cell at the EU PVSEC conference. The cell consists of a top perovskite cell developed by imec within the partnerships of EnergyVille and Solliance, and a bottom CIGS cell from the Centre for Solar Energy and Hydrogen Research (ZSW, Stuttgart, Germany). The tandem cell resulting from this collaboration achieves a record efficiency of 24.6%.

The perovskite top cell in the tandem uses light in the visible part of the solar spectrum, while the light in the near-IR spectrum that passes through the perovskite cell is harvested by the underlying CIGS cell. In this way, the tandem cell significantly outperforms the stand-alone perovskite and CIGS cells. Moreover, both perovskite and CIGS cells are thin-film solar cells, paving the way to high efficiency flexible solar cells and building integrated photovoltaic (BIPV) solutions.

Pagination

- Page 1

- Next page