![]() Greatcell Energy was formed following Greatecell Solar's liquidation. Greatecell Energy acquired all of Greatcell Solar's IP, equipment - and Italian subsidiary.

Greatcell Energy was formed following Greatecell Solar's liquidation. Greatecell Energy acquired all of Greatcell Solar's IP, equipment - and Italian subsidiary.

The company's main focus is on the low-light, indoor IoT market. Using a roll-to-roll low-cost method, the company developed a high-efficiency perovskite indoor solar panel and is now upscaling its facilities for production.

Greatcell energy also has a long term full-sun research program with several universities and large innovative corporations.

52 Bergamont St

Elanora QLD 4221

Australia

Halocell to start producing indoor perovskite PVs that can replace disposable batteries and charger cables

Australian start-up Halocell will reportedly begin producing flexible 7 centimeter-long photovoltaic strips that are said to generate enough power to replace the pair of disposable batteries in a TV remote, or the charger cable for a set of headphones. This represents the first large-scale manufacturing in Australia of perovskite PV technology.

The 5-volt Halocell perovskite strip. Image credit: Halocell

The Halocell modules will each cost less than a dollar to make and the Company has ambitious plans to produce millions per year, its CEO Paul Moonie said.

Researchers improve the stability of perovskite solar cells with novel encapsulation method

Researchers at CHOSE (Centre for Hybrid and Organic Solar Energy, University of Rome Tor Vergata), BeDimensional, Istituto Italiano di Tecnologia and GreatCell Solar Italia recently addressed the stability issues presented by perovskite solar cells, by developing an industrial encapsulation process based on the lamination of highly viscoelastic semi-solid/highly viscous liquid adhesive atop perovskite solar cells and modules.

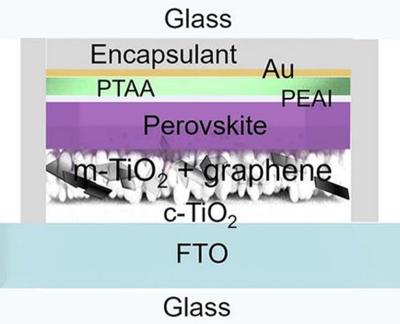

Sketch of the structure of the mesoscopic n-i-p PSCs. Image credit: Nature Communications

The encapsulant reportedly reduces the thermomechanical stresses at the encapsulant/rear electrode interface. The addition of thermally conductive two-dimensional hexagonal boron nitride into the polymeric matrix improves the barrier and thermal management properties of the encapsulant. Without any edge sealant, encapsulated devices withstood multifaceted accelerated ageing tests, retaining >80% of their initial efficiency.

First Graphene, Halocell and QUT secure funding for perovskite PV project

Graphitic materials supplier First Graphene has announced an R&D collaboration with Greatcell Energy, trading as Halocell Energy, and the Queensland University of Technology (QUT) to commercialize perovskite solar cell fabrication. The project has received a Cooperative Research Centers Project (CRC-P) grant worth over AUD$2 million (around $USD1,300,000).

The research and development project is intended to commercialize ultra-low-cost, flexible perovskite solar cell fabrication using Halocell’s roll-to-roll production process at the company’s Wagga Wagga plant, First Graphene said in an announcement. Through the project, First Graphene plans to develop cost-effective graphene-based electrode replacements for high-cost conductor materials, such as gold and silver, used in cell manufacturing.

Greatcell Australia and First Graphene explore graphene enhancements to perovskite solar cells

It was recently reported that Greatcell Australia is working with graphene company First Graphene on graphene enhancements to perovskite solar cell technology.

Greatcell Australia has reportedly established a pilot plant in New South Wales and is in the advanced stages of testing its range of perovskite solar cells (PSCs) with manufacturers around the world. “Greatcell is aiming to modularize their production lines for product flexibility, due in part to the easier assembly and reduced number of steps to produce PSCs compared to silicon solar cells.”

Perovskite solar cells show improved stability and renewable capability with the use of polyvinylpyrrolidone polymer

Researchers from the Hefei Institutes of Physical Science (HFIPS) under the Chinese Academy of Sciences (CAS), University of Science and Technology of China, North Minzu University, Hefei University of Technology, Greece's Institute of Nanoscience and Nanotechnology (INN) and Australia's Greatcell Energy have developed perovskite solar cells with a self-recovery capability and high stability in humid environment by introducing polymer called polyvinylpyrrolidone.

The team has shown that polyvinylpyrrolidone, a long chain insulating polymer, could form hydrogen bonds with ions in the cells and also prevent moisture in the air from invading perovskite materials. The hydrogen-bonding-initiated self-healing repairs the decayed perovskite solar cell back to the original state, continue to work, and alleviate long-term cell instability.

Pagination

- Page 1

- Next page