Researchers from CHOSE (Centre for Hybrid and Organic Solar Energy) at Tor Vergata University of Rome, CNR-ISM and Saule Technologies have introduced an optimized blade coating process for the scalable fabrication of large-area (15 cm × 15 cm) perovskite solar modules with a nickel oxide hole transport layer, performed in ambient air and utilizing a non-toxic solvent system.

The research group fabricated a 110 cm² perovskite solar module with an inverted configuration and a hole transport layer that uses nickel oxide instead of commonly utilized poly(triarylamine) (PTAA). The proposed architecture aims to achieve high efficiency that is competitive with PTAA-based panels while improving stability.

In inverted perovskite solar cells and modules, the perovskite cell material is deposited onto the HTL and then coated with an electron transport layer (ETL) – the opposite way compared to a conventional device architecture. Inverted perovskite solar devices typically show strong stability, but have lagged behind conventional devices in terms of conversion efficiency and cell performance.

The scientists explained that inverted perovskite cells commonly utilize an HTL based on poly(triarylamine) (PTAA), which they said is known for its high performance in printable devices. Their choice for NiOx was due to the enhanced long-term stability this material offers, on top of similar efficiency levels compared to PTAA. They said that in contrast to PTAA, NiOx is potentially low-cost due to its inorganic nature, is highly photostable, chemically stable, has excellent optical transmittance, and has a hydrophilic nature.

The scientists warned, however, that integrating the NiOx HTL under ambient conditions using printable methods results in lower efficiencies compared to PTAA-based devices. To solve this issue, they decided to print NiOx over the cell, without any spin coating step, via so-called doctor blading, a method generally used to form films with well-defined thicknesses.

The team did the doctor blading of nickel(II) chloride (NiCl2·6H2O) solution on indium tin oxide (ITO) substrates in ambient conditions. Then, the films were annealed at 300 C to promote decomposition and oxidation, leveraging atmospheric oxygen to form the NiOx film.

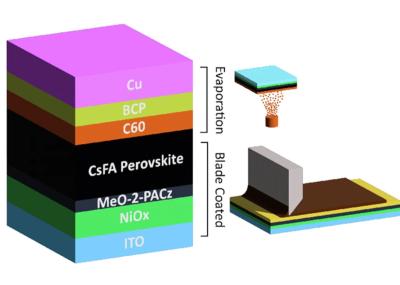

The solar panel was built with an ITO substrate, the NiOx HTL, a self-assembled monolayer (SAM), a perovskite absorber, an ETL relying on buckminsterfullerene (C60), a bathocuproine (BCP) buffer layer, and a copper (Cu) metal contact.

The first four layers were fabricated via doctor blading in ambient conditions, while the remaining ones were assembled via thermal evaporation.

Tested under standard illumination conditions, the 110 cm² perovskite panel achieved a power conversion efficiency of 12.6%, a short-circuit current density of 19.67 mA/cm2, and a fill factor of 63.49%. The device was also able to retain 84% of its initial efficiency after 1000 h of thermal stress testing at 85 C in air.

The team stressed that these results underscore the potential of NiOx in PSCs and open new avenues for the large-scale, cost-effective production of perovskite solar modules.