Researchers from the University of Stuttgart, Lawrence Berkeley National Laboratory and Brandenburg University of Technology Cottbus-Senftenberg have introduced a simplified deposition procedure for multidimensional (2D/3D) perovskite thin films, integrating a phenethylammonium chloride (PEACl)-treatment into the antisolvent step when forming the 3D perovskite.

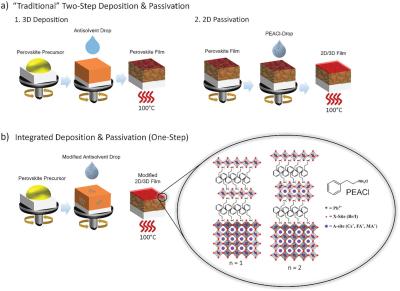

The “traditional” deposition and passivation processes (top row) and the integrated deposition and passivation strategy to form 2D passivated 3D halide perovskite films (bottom row). Image from Advanced Materials.

This recently developed simultaneous deposition and passivation strategy reduces the number of synthesis steps while simultaneously stabilizing the halide perovskite film and improving the photovoltaic performance of resulting solar cell devices to 20.8%.

Using a combination of multimodal in situ and additional ex situ characterizations, the team demonstrated that the introduction of PEACl during the perovskite film formation slows down the crystal growth process, which leads to a larger average grain size and narrower grain size distribution, thus reducing carrier recombination at grain boundaries and improving the device's performance and stability.

The team's work suggests that during annealing of the wet film, the PEACl diffuses to the surface of the film, forming hydrophobic (quasi-)2D structures that protect the bulk of the perovskite film from humidity-induced degradation.