Oxford PV recently stated that it hopes to deliver perovskite-silicon tandem solar cells to high end solar module manufacturers in the first half of 2021, now less than a year away.

The group expects these solar cells to have an efficiency between 26-27%, to increase in efficiency by 1% per year as the company improves its manufacturing techniques. It was said that initially, a 400 watt 60-cell solar module will probably be available.

Oxford PV's CEO, Frank P. Averdung on the timeline for these cells being available to the market: ''All of our facilities (in Brandenburg) are in place to accommodate equipment. The initial equipment arrived, and we intend to have this Meyer Burger heterojunction line installed by mid year. The dedicated perovskite equipment will be installed during the second half of the year, with the full line running by the end of the year. By mid 2021, we'll be at full production''.

Oxford PV says at full production capacity they'll produce 125 MW/year of solar cells. As well, the infrastructure in the Brandenburg facility is enough to quickly double that capacity.

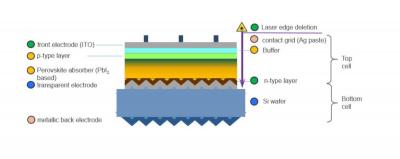

Oxford PV uses processes and equipment they've designed that apply layers of a 'wide bandgap perovskite.' CTO Chris Case noted: ''It's just thin layers of perovskite. We're building an integrated solar cell production line of heterojunction bottom cells, and attaching to that a production line of a couple of additional tools that add these specialized layers. In the end, out comes boxes of standard looking solar cells ' but with higher efficiency''.

Oxford PV assumes they'll first sell into the 60 cell residential solar module market. This makes sense as the market does tend to pay more for its modules and seeks higher efficiencies. the expectation is to spread out to other markets soon after.

The company says their hardware can adjust to larger sized solar cells now being manufactured. Which fits in with another business plan ' the integration of Oxford PV machines into already existing heterojunction solar module lines around the world. T

Covid-19's need for isolation has led to a restructuring of the Brandenburg solar line assembly group into two independent teams. The cross trained engineers are concurrently working on both line and process integration.

It was noted though, if the Covid work shut down goes beyond three months, timelines will be stressed. Averdung said: ''Things are dependent on each other. First, the facility needs to be ready, we are there. Second, Meyer Burger needs to deliver the heterojunction line, and they have! We are extremely pleased with them, all the tools came in when expected. Another is that the existing pilot line need give enough wafers to build a significant number of modules for precertification. Panels must go into testing in Q3. If the pilot line is down ' if work stoppages are extended ' then that will have an impact''.

Oxford says work has slowed a bit, but even with the teams completely avoiding each other, timelines are currently intact.