Colloidal perovskite nanoplatelets (NPLs) have shown promise in tackling blue light-emitting diode challenges based on their tunable band gap and high photoluminescence efficiencies. However, high quality and large area dense NPL films have been proven quite hard to prepare due to their chemical and physical fragility during the liquid phase deposition.

Recently, researchers from University of Groningen reported a perovskite-polymer composite film deposition strategy with fine morphology engineering obtained using the blade coating method. The effects of the polymer type, solution concentration, compounding ratio and film thickness on the film quality were systematically investigated and the team found that a relatively high-concentration suspension with an optimized NPL to polymer ratio of 1 : 2 is crucial for the suppression of phase separation and arriving at a uniform film.

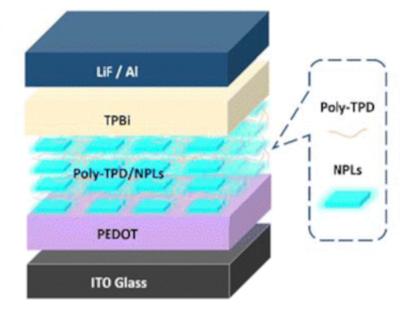

This work demonstrates a convenient strategy for preparing uniform and non-aggregated blue-emitting CsPbBr3 NPL/polymer composite thin films via blade-coating at room temperature. Two very common hole transport polymers, namely, poly(9-vinylcarbazole) (PVK) and poly(4-butyl-N,N-diphenylamine) (P-TPD), were each used as a matrix to form corresponding composite films with NPLs.

The study revealed that using a compatible polymer in a highly concentrated suspension is indispensable for suppressing phase separation and forming conformal and compact films. The scientists fabricated sky-blue NPL-based perovskite light-emitting diodes by blade coating, showing an EQE of 0.12% on a device area of 16 mm2.