Researchers from Ulsan National Institute of Science and Technology (UNIST), Korea Electrotechnology Research Institute (KERI) and Sungkyunkwan University (SKKU) recently developed a straightforward and effective method for producing 3D architectures of perovskite quantum dot (PQD)-encapsulated high-performance composites (PQD-HPCs) through direct-ink writing (DIW).

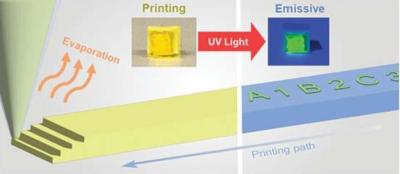

Schematic of the direct-ink writing (DIW) approach of luminescent PQD–polymer architectures. Image from Advanced Functional Materials

Led by Professor Im Doo Jung from the Department of Mechanical Engineering at UNIST, the recent study introduced a cutting-edge one-stop perovskite quantum dot (PQD) additive manufacturing technology. This approach eliminates the need for heat treatment, allowing for the creation of complex 3D shapes with exceptional precision, including iconic landmarks like the Eiffel Tower.

Traditionally, shaping QD materials in 3D required prolonged heat exposure, leading to property degradation and shape deformation. However, the newly developed PQD materials exhibit remarkable luminous efficiency and color versatility, offering a novel solution for advanced encryption and anti-counterfeiting applications.

By meticulously optimizing key printing variables and utilizing hydroxypropyl cellulose (HPC) polymer and dichloromethane (DCM) as a volatile solvent, the research team achieved stable extrusion of luminescent PQD inks at room temperature. This innovative 3D printing method enables the creation of diverse structures emitting light in red, green, and blue (RGB) colors based on the primary light colors.

The study introduces a sophisticated anti-counterfeiting and encryption system utilizing 3D-printed geometric shapes that leverage the unique light emission properties of PQDs. Demonstrating the potential for enhanced security features in modern printed electronic devices, a 6 x 5 cube architecture array was designed using G- and B-emissive PQD-HPCs for encryption, displaying alphabetic letters (U, N, IS, and T) at 90° intervals.

Lead author Hongryung Jean said, "Our streamlined QD 3D printing process enables stable manufacturing at room temperature, promising advancements in information encryption systems and optoelectronic printing technologies."

Professor Jung said, "This advancement preserves the photoluminescence properties of PQDs without the need for heat treatments, driving innovation in optoelectronic and energy applications."