Verde Technologies launches new research lab and pilot production facility in Waterbury Center

Verde Technologies has opened a new research lab and pilot production facility in Waterbury Center, Vermont, which will aim to allow the company to build out its pilot lines and start producing larger thin-film solar cells for upcoming pilot projects with local and national partners.

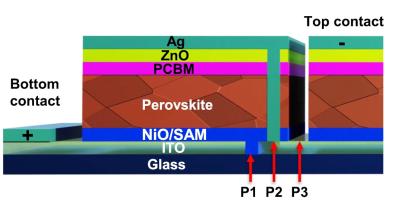

The research center is located in the former Suss Microtec facility. Verde's lead investor is VCET's Vermont Seed Capital Fund. Founded in Burlington by University of Vermont alums and researchers, Verde Technologies manufactures thin, lightweight and flexible perovskite solar panels. The Company says that "these American-made and manufactured panels are ten times lighter than traditional silicon solar panels and use a peel-and-stick installation method making them much more accessible and affordable". Verde’s technology will allow them to repower older solar fields to increase their output and utilize existing infrastructure.