Scientists from Gwangju Institute of Science and Technology (South Korea), Hanwha Solution (South Korea), Korea Research Institute of Chemical Technology (South Korea), Imperial College London, Stony Brook University and U.S. Brookhaven National Laboratory have developed a new material processing protocol to boost the operational stability of planar hybrid perovskite solar cells.

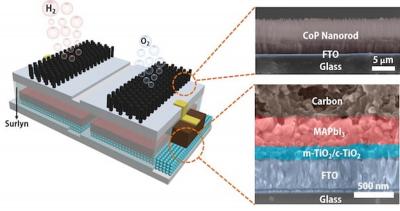

A schematic showing the vacuum and solvent process for removing the ionic defects that reduce the performance of hybrid perovskite solar cells.

A schematic showing the vacuum and solvent process for removing the ionic defects that reduce the performance of hybrid perovskite solar cells.

Typically, thin-film devices are made in solution by sandwiching the active light-absorbing material in between top and bottom metal electrical contacts (electrodes) and organic semiconductor interlayers, which enhance the extraction of electrical currents to the contacts. In this case, before putting the final electrode on top, the scientists put the device in vacuum. In prior experiments, the team had noticed that removing and then redepositing the top electrode and interlayer reduced burn-in loss, a rapid decrease in efficiency at the beginning of light illumination. They subsequently confirmed that the high-vacuum environment used to deposit the electrode had contributed to this reduction. During vacuum curing, loose ions emerge from the perovskite and concentrate at the top interlayer. In a second processing step, the scientists used a chemical solvent to selectively wash away this top layer.